Optimization: Water Treatment Facility

Water treatment plant operators take on heavy responsibilities to ensure their city treatment facility is operating correctly. With chemicals, equipment, temperatures and fluctuating water sources, there’s a lot that goes into ensuring optimal performance.

Water treatment plant operators take on heavy responsibilities to ensure their city treatment facility is operating correctly. With chemicals, equipment, temperatures and fluctuating water sources, there’s a lot that goes into ensuring optimal performance.

With so many factors to monitor, it’s likely easiest for an operator to test, make adjustments as needed to ensure water is safe, and proceed with operations. It’s human nature: when things fall within the recommended parameters, we happily go on with the day, sparing time that could be spent tracking the happenings of such a tedious operation.

No matter the type of treatment plant, test results should be documented daily, at a minimum. The data collected will serve multiple purposes.

Data is the largest element to plant optimization, diagnostics, troubleshooting and planning for the future. The records kept may not feel beneficial while the plant is operating smoothly, but when operators need help troubleshooting, we need data to refer to.

When our professionals visit with operators, the first thing we typically ask for is their data. Troubleshooting is very difficult if you don’t have testing history. The better data an operator can supply, the better off we are.

OUR TIPS:

1.) If you haven’t been tracking your operation, start.

2.) Be sure the results tracked make sense. If you aren’t doing the testing right, your data will lack the true indicators needed to troubleshoot.

3.) Work with a trained professional to learn what types of testing you should be doing, how to properly do the testing and develop skills to detect what the results mean.

Here are some things to track:

- Water production and usage

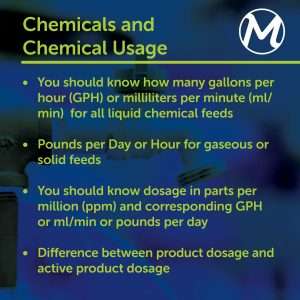

- Chemicals and chemical usage

- Water testing – source and finished water

- Operating procedures

- Water quality tests and chemical inventory so you know when to order more lime or chlorine

- Maintenance logs to document 6- or 12-month recurring events

Plans

Create a process flow diagram. This is a simplified version of what the contractor builds that will help you understand how it works. Having such a diagram is good to have on hand because, as an operator, you’ll know where the chemicals are being added and you’ll know which way the process is supposed to go and where it flows.

Smooth Operator – with room for improvement?

In water treatment plants, operators should gather data daily on both raw water and finished water to see how your plant is performing. Water quality data in between treatment processes is

also helpful to determine if the individual processes are working as needed. If you’re a 24-hour production plant, this should be done several times a day. Wells and rivers change – especially in the fall and spring – it’s important to check those regularly.

We recognize not every operator has this kind of time. There are other tests we can help run that won’t be as time intensive.

TIP:

There are easy adjustments you can make based on pH alone in some plants. It’s best to have a professional come in, walk through the plant with you and evaluate what you’re doing to find areas to boost efficiency and accuracy.

Water Production

The difference between what is sold in a city and what the plant pumps out is the water loss, whether it goes to the city swimming pool, fire station or just being lost through a pipe break. If there is more than a 10% loss, you should investigate where the water is going, because you could be losing revenue.

If the loss is greater than 10%, check your meters. Make sure everything has a meter on it, and make sure the meter is not too large, as large meters may not read correctly.

Optimizing your water tower

Optimizing your water tower

If water is in a tower too long, it can cause Disinfection Byproducts, or DBPs. This occurs when disinfectants such as chlorine start to break down and interact with natural material present in water. Long-term exposure can cause a variety of health risks, so it is important to monitor DBPs by regularly sampling your water.

To prevent this, you can add mixers in the water tower to reduce DBP formation and to prevent ice buildup.

If you would like more information about optimizing your water treatment facility, give us a call.